Hello

Hard to post right now, when you don’t know what to say it’s better telling nothing.

Rapid catch-up session, I hope it will please you, let’s go ?! 😉

One must place it on something this machine …

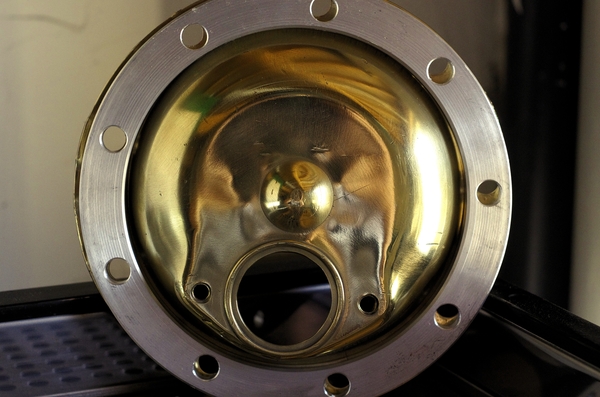

One thing bothered me about this machine was broken boiler flange, a 9 holes not to be found to my knowledge. I made remanufacture. For recall, too, this machine only worked at gas, so the flange was not drilled. There was an impression of the passage hole of the heating element, and two brass round welded inside at the location of two clamping screws.

Drilling main hole. Drilling and threading of the two holes who maintain the heating element.

Creating a branch connection on the steam circuit for the installation of the p-stat.

I replaced the group. The original was one designed for French market. Not interesting for espresso and too hard and expensive to find the gaskets.

The machine now is quite finished. I finish rincing the boiler tomorrow and will soon make an espresso. I just have to finish painting the front glass and install the red light.

A few pictures again.

Pascal