Hello all

I’m late … I was able to clean the boiler, I had to sand the bottom which was attacked by a large enough surface rust. You have to understand the “operation” of stainless steel, this is not the material itself which is stainless but its reaction to the air. Contact with oxygen causes first-oxidation, called passivation, which will form an airproof and liability layer, a certain thickness becomes stable.

Rust on stainless steel occurs when the passive layer is attacked by an aggressive agent, it can be a grinding, welding, chemical attack, such as hydrochloric acid, completely prohibited. The use of tools that have been in contact with ferrous metal may even be causing a problem. I think the boiler had to be cleaned with steel wool, obviously there was a leak at the low pressure valve, and the protective layer has been weakened, the iron powder came into contact with bare metal and rust. This layer prevents good passivation of stainless steel and corrosion gradually takes over.

To facilitate the return to normal of the surface sanded, then assaulted, I had to polish the tank to find a smooth surface more conducive to “good” oxidation.

I also back up all the piping, hoping not to have to undo all later… normally it should be fine, at least… I hope 🙂

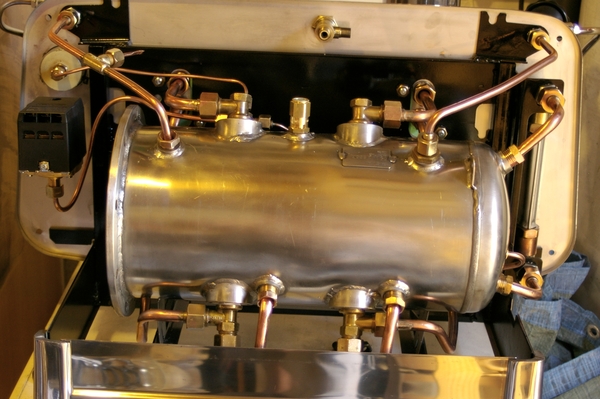

A small picture of the result: