Hello everyone

It all started very well, a lot of work but no surprises.

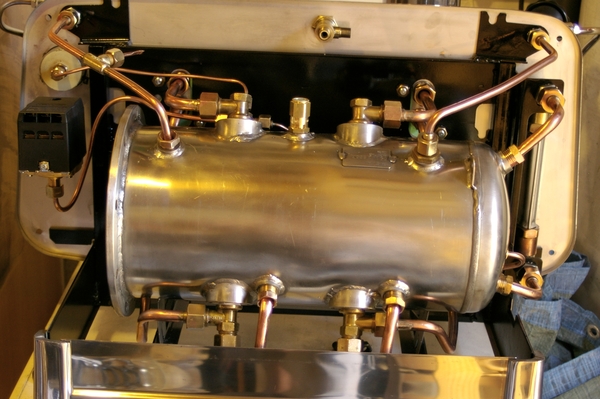

In two days, I got my account … first, before yesterday, impounding of the machine, cold because I was still waiting last parts to finish the two groups.

I plumb the machine after checking that everything was tight and I gently open the water. I begin to fill the boiler and I have a leak to the flange of the machine, nothing serious, I tightened and it will be resolved.

Ditto for the HX group left, down, it was not tight enough either.

I get to the water inlet valve and a leak on the arrival side, just after the valve which is connected to the hose. I must say that it lacks a bit of tightening and also is sending a bit of a key. It still leaks …. I tighten again but it still leaks, and rather more, I decided to take apart.

Final observation, the female fitting olive is split a bit of everywhere …

This is particularly annoying because this piece is no longer anywhere, it will therefore be necessary that I find a solution. I decided to change the connector fitting flat, which I add a joint. I cut the most damaged, then I grinded a dish. Solder to fill the last remaining micro cracks and re grinding to rebuild a correct range. Even the olive processing and assembly of the pipe. That is, I was a bit scared but finally it will not happen.

Yesterday I finally received the two piston pins that I missed to get all groups, then wound a little laborious, new pistons have been complicated to screw on the axes by compressing the springs, but it was finally done and groups are operational.

Last evening, the machine is hot, a small leak in the last connections thermosyphon groups and everything is ok. First coffee to rinse the machine then it is 22h so I decided to stop.

Today I put the machine on, I rinse a little more and decide to taste my first coffee, very happy to finally arrive at the end of this project. This afternoon, after dinner coffee will be taken on the machine and frankly, it’s really beautiful, the reputation of this group really is not stolen.

This afternoon, I put a little workshop, and at some point I fell not far from the machine, eye level with the bottom, I see a drop down, I go and there actually a small puddle under the boiler. Inspection, and it is a disaster …. there are two tiny pinholes in the bottom of the tank ….

I will have to take the boiler apart again and weld both holes by a specialist, I can not weld stainless steel and do not have the necessary equipment.

So … following the re re-assembly…