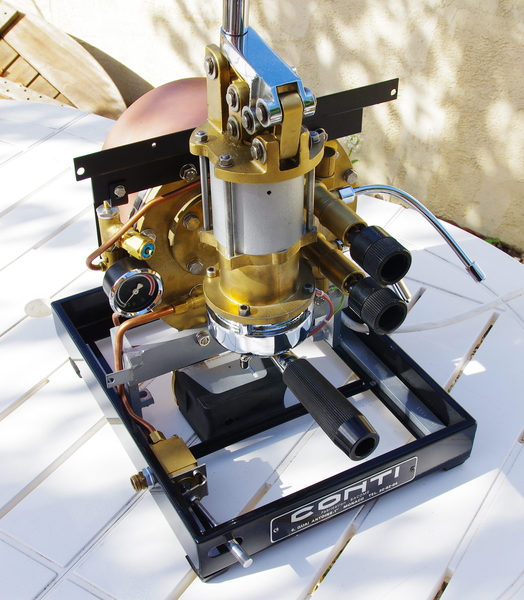

Definitely not easy posting through here now, here are some details of ongoing work. Today the machine makes coffee, It only remains me to polish the stainless steel skins, reassemble the body, and it will be over. But you understand, I’m late here.

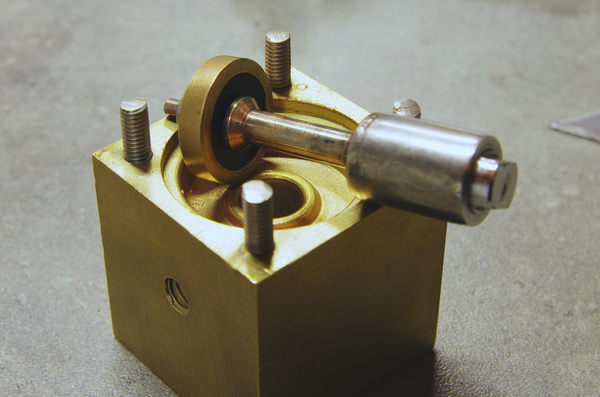

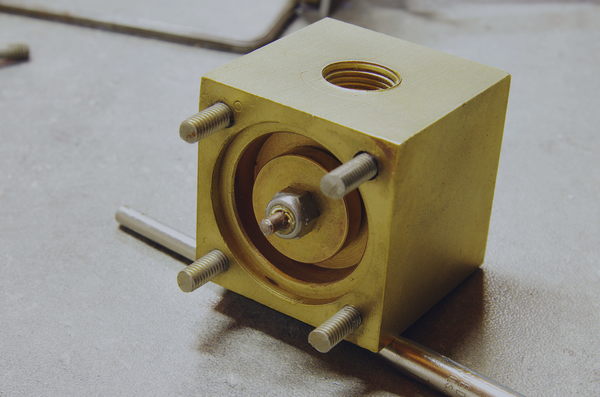

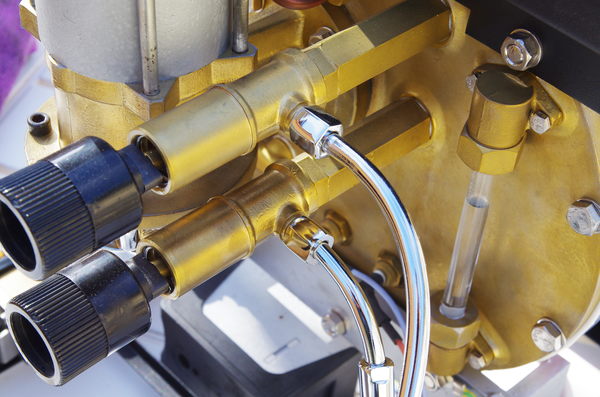

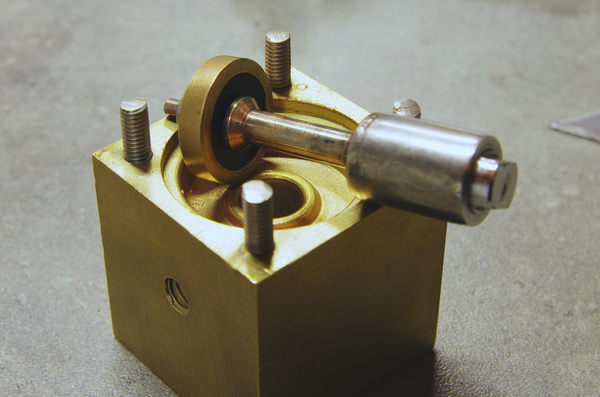

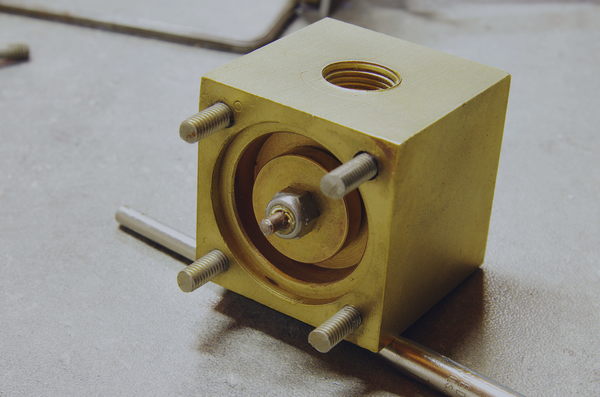

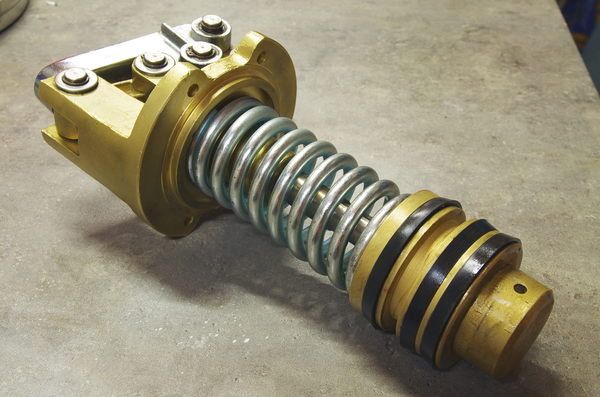

During reassembly of the water inlet tap I made some pictures. I really love this assembly. It is as firmly and intelligently designed as a tap at Unic. Except that in addition ergonomics for assembler has been very well thought out. No need to pick a hidden O-ring in a small hidden deep throat of a well … Here everything has been designed to be very accessible.

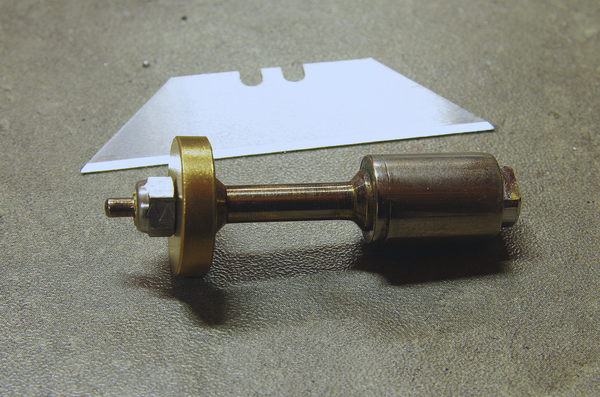

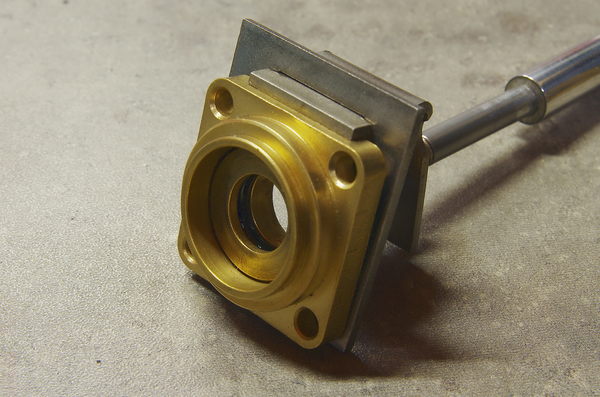

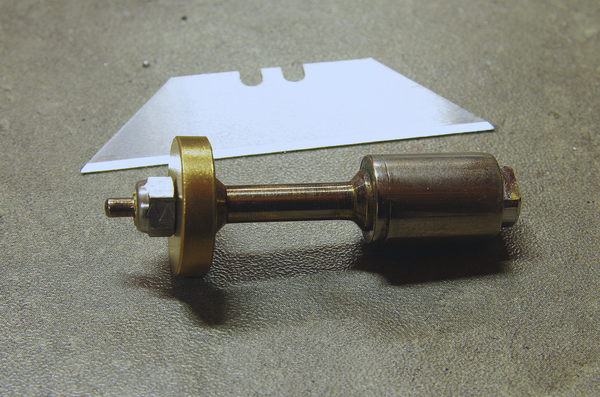

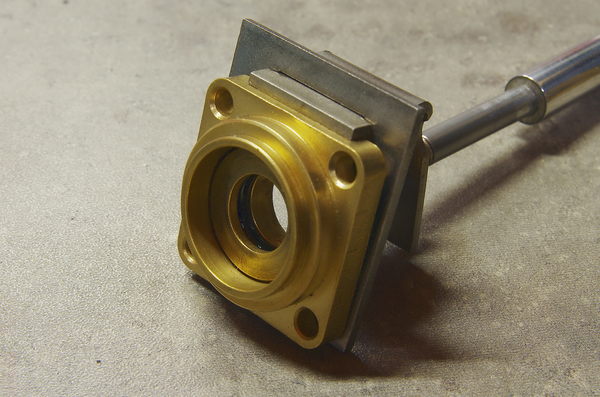

Here is the main button controlling the opening of the valve :

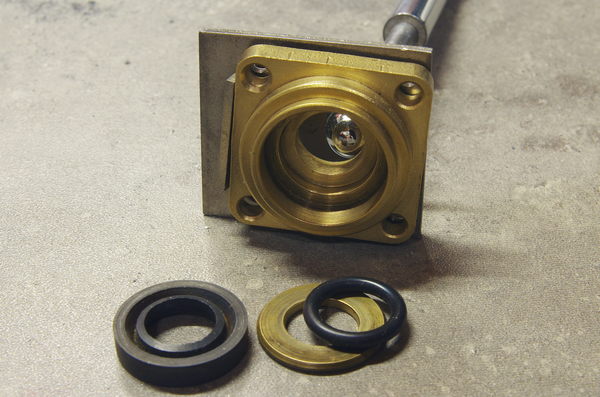

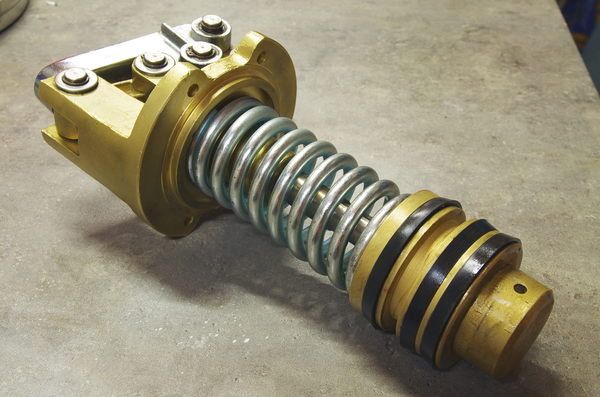

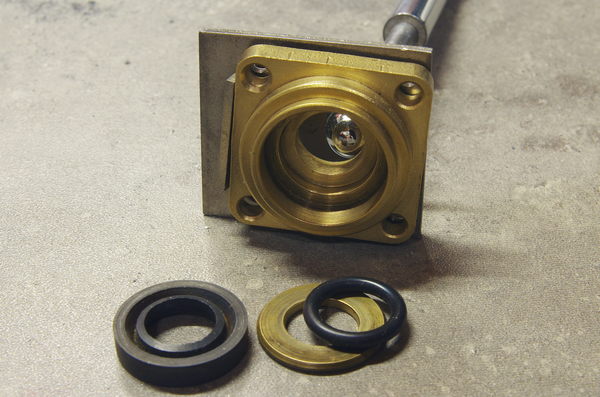

The O-ring guiding the piston of the tappet is first placed in a groove cut into the body. Once placed the copper washer maintain it. Just over, the v-seal makes the sealing of the piston, and everything is maintained by the cover. So obvious!

As often with the manufacturers, a gasket is used for many purposes. The valve O-ring above is the same as that necessary to seal the two bases of the water level tube. Fortunately I had ordered several.

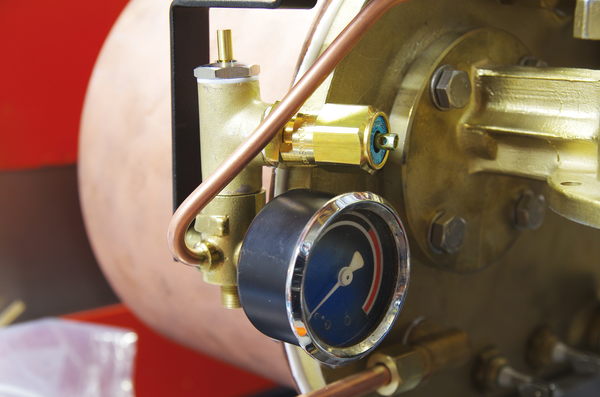

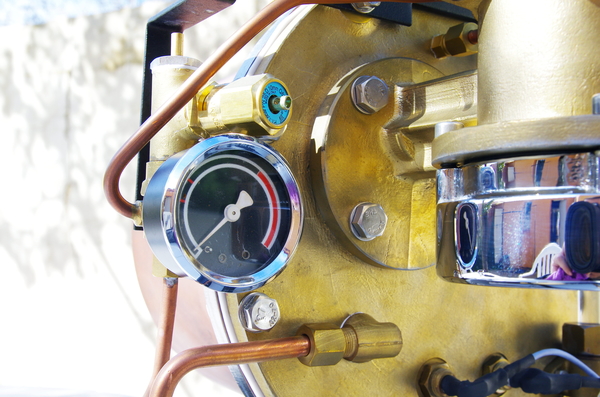

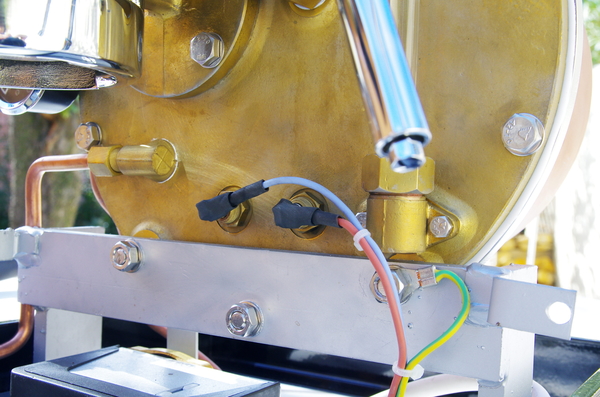

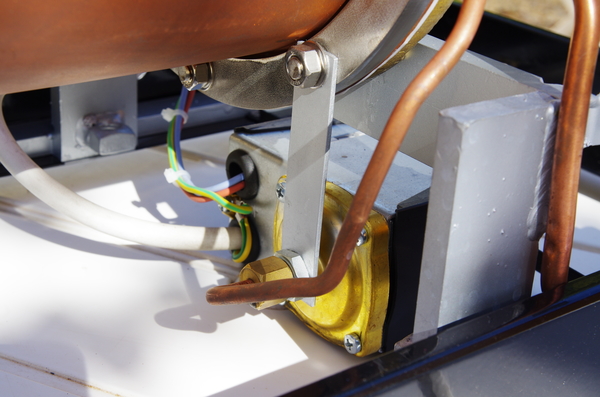

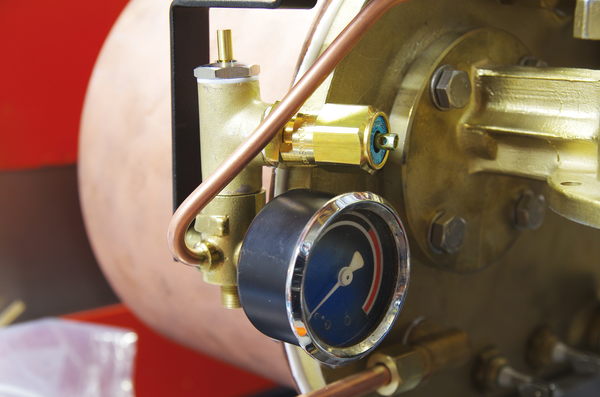

The heating element comes from the catalog La Spaziale, « Professional » model. Big advantage for all since Conti doesn’t produce it any more. And big advantage for our American friends, as it also comes in 110v. Details of the seals I used and hot water draw-off.

Not easy to fit a false steam/vacuum breaker valve with the OPV, not too much space…

Awesome this group, love it.

Nice Sunday, I try to come back very soon to talk about the end of this restoration.

Pascal

Comme d’habitude superbes photos,

Bravo Pascal

Merci beaucoup Ludo !

Pascal,

You have me very excited for me to start working on my Conti Prestina. Such a beautiful machines, n’est pas? I got lucky and picked up a Comocafe too.

Hi Cher, nice machine too the Comocafe !